Part #: EFC818-X-XXX-XX

At the input and output fiber end face in high power lasers (100’s, 1000’s even dozens of thousands of watts), the energy density can be very high. So if the laser radiation transmits to the fiber end face, there is a high risk of burning or degrading the fiber.

An end cap on the end face of fiber is a good solution for this issue – an 8mm diameter end cap spliced to the fiber can greatly increase the diameter of the beam spot, which is a very effective method to lower the power density.

On the surface of the end cap, a high damage threshold AR coating is applied, while on the other side of the fiber, a high efficient cladding power stripper (CPS) is added. Most importantly, it’s epoxy free.

We have very high power passive fiber optic devices such as couplers – please ask.

Specifications

| OPTICAL PARAMETERS | SPECIFICATIONS | |

| Operating wavelength range | 900-1100nm | |

| Cladding power stripper | Stripping efficiency>20dB, Signal IL<0.1dB | |

| AR coating | Reflection rate at all wavelength range<0.2% | |

| Fiber type | LMA DC fiber | 20/400DCF, 25/400DCF, cladding dia. up to 600um |

| BD fiber | 50/360, 100/360, 200/360 0.22NA etc. The fiber core dia. up to 1.5mm and cladding dia. up to 2mm |

|

| Fiber & end cap concentricity | ≤20um | |

| Beam angular deviation | TBD | |

| MECHANICAL PARAMETERS | ||

| Single/Double connectors | 0.5m bare fiber (onl in single connector version), or double connectors | |

| Water flow rate | ≥1.7L/min | |

| Cable configuration | O.D. 11.5mm, I.D. 9mm, with inner Teflon tube (O.D. 8mm, I.D. 6mm) | |

| Cable length | 5m, 10m, 15m, 20m, etc. (can be customized) | |

| Protection window for end cap | Assembled on the EFA, replaceable, with one extra for backup | |

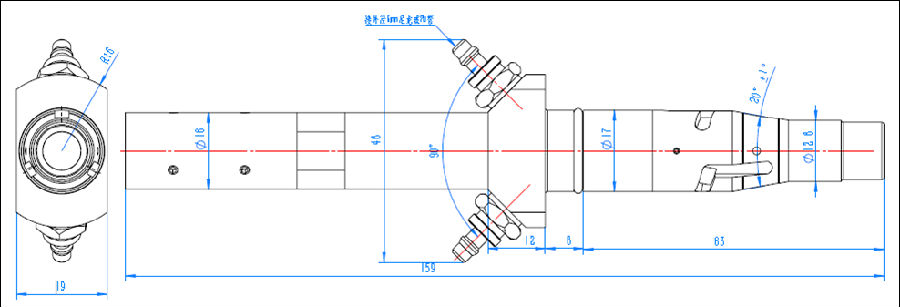

Configuration description (Patent applied)

Step 1. Make 30mm long cladding power stripper on fiber cladding, tested with 390W stripping power, the fiber surface temperature is <30℃.

Step 2. Splice 8mm end cap with fiber, proof test <20N.

Step 3. Splice a quartz tube with end face, to pretect CPS area for cooling water.

Step 4. Assemble mechanical parts.

Schematics

Remarks:

– The thicker a fiber cladding diameter is, the higher pull force it can bear.

– At present, no quartz tube to protect CPS for the fiber cladding diameter thicker than 600um, so the CPS area will be exposed in cooling water.

Further Info

| FEATURES | – Fiber spliced to 8mm cap, passed proof test & vibration test. – A cladding power stripper (CPS) is made near the end cap, featured in high stripping efficiency, low loss in fiber core, epoxy free and cool fiber. – High demage threhold AR coating on the surface of end cap can decrease transmission loss. – A quartz tube is added to isolate stripping area with cooling water, which can also protect it from polluting by water. – Complied with QBH. – RoHS complied. |

| APPLICATIONS | Output with Fiber Laser | Solid state Laser and fiber coupled diode Laser | Accessories of Laser machine |

| REGION | All |

Ordering Info

Part # format: EFC818-A-B-C

| A | Configuration S = Single head D = Double heads |

| B | Fiber code Please find in fiber code list below |

| C | Fiber length 05 = 5m 10 = 10m 15 = 15m 20 = 20m |

PN Example: EFC818-S-LD420-05

| Fiber type | Code | |

| Double Cladding Fiber | 20/400 DCF | LD420 |

| 25/400 DCF | LD425 | |

| 30/400 DCF | LD430 | |

| 30/600 DCF | LD630 | |

| Beam Delivery Fiber | 200/240 0.22NA | B220 |

| 50/360 0.22NA | B305 | |

| 100/360 0.22NA | B310 | |

| 200/360 0.22NA | B320 | |

| 300/360 0.22NA | B330 | |

| 200/500 0.22NA | B520 | |